Safety Updates 2018

Three-year action plan

Developed in 2016 in consultation with leaders and now in its final year, EHS’ three-year safety action plan is well on track and has been successful in advancing safety significantly.

Summary of safety action plan

This table highlights the three year action plan for EHS from July 2016 - June 2017 (Year 1) to July 2018 - June 2019 (Year 3). In the past year, the programs scheduled to be developed included Noise Control Program, Risk Assessment Framework, Working From Heights, and Lab Safety. All successfully completed.

Key highlights from Year 2

Noise control program

University-wide noise assessments were completed and a corresponding noise control program was developed. Further work is underway in implementing the controls with lab, studio and maintenance areas.

Risk and hazard assessment

We have standardized risk and hazard assessment templates in all of our safety programs and training to assist our community in making risk-informed decisions

Working at heights

In addition to the existing working at heights safety procedures, an assessment for working at heights from roofs has been conducted. Work is underway to incorporate additional controls where necessary.

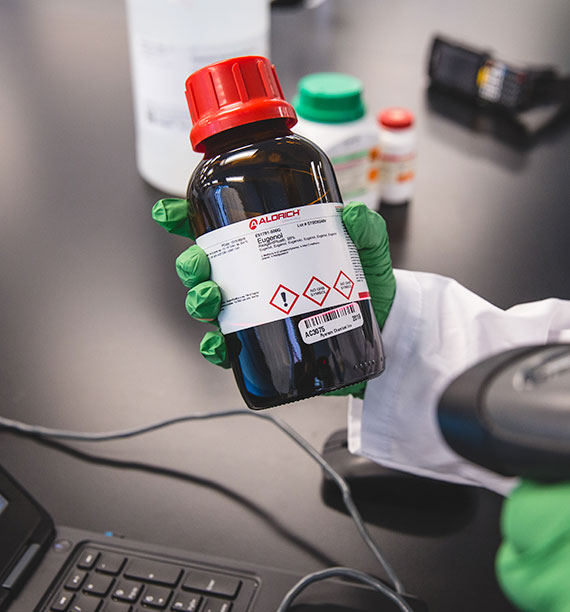

Lab and chemical safety programs

Comprehensive programs for both lab safety programs and chemical safety have been developed and implemented.

High voltage and arc flash risks assessments

In collaboration with the FMD maintenance and operations team, an assessment was conducted for high voltage and arc flash risks to protect employees working with live electricity.

Designated substances

Ontario legislation includes 11 designated substances (external link) . In 2018, Ryerson completed a inventory of all our designated substances and is now developing control programs where applicable.

Safety training

Safety training for both students and employees allows us to ingrain safety into our work and learning culture. The university offers safety training in various forms to accomodate all types of learners including in-class sessions, YouTube videos (external link) , eLearning, and through Safe Operating Procedures that are available online as well as in the form of QR codes.

We offer a comprehensive suite of training including laboratory, machine shop, role-specific and hazard- specific.

Mandatory eLearning courses

In 2018, EHS launched two mandatory e-learning courses for all employees.

Environmental Health and Safety eLearning

Environmental Health and Safety eLearning highlights an employee’s environmental health and safety rights and responsibilities, as outlined in the Ontario Occupational Health and Safety Act and Ryerson’s Policies and Programs.

Workplace Hazardous Materials Information System (WHMIS) Awareness eLearning

Workplace Hazardous Materials Information System (WHMIS) Awareness eLearning provides users with information on the new WHMIS 2015 requirements. It is designed to introduce you to the new symbols, safety data sheets and labelling requirements for hazardous (chemical) and controlled products. It is designed to introduce them to the new symbols, safety data sheets, and labelling requirements for hazardous (chemical) and controlled products.

Employees who work in areas where hazardous materials are used (i.e. wet labs or research involving chemical use) are also required to take an additional Chemical Safety module. For details on accessing this module, visit the Chemical Safety course information on the Facilities Management and Development website.

In-class safety training in 2018

This chart highlights the number of participants in various in-class safety training sesions. The two largest courses were Biosafety with almost 100 particpants, followed by Fire Extinguisher Training with almost 80 participants.

In 2018, the EHS team offered almost 35 in-class safety training sessions on over 20 different topics.

Joint Health and Safety Committee

Joint Health and Safety Committees (JHSC) include both union and management members and make recommendations to advance workplace safety within organizations.

Front row left to Right: Zahid Patel, Amanda Barber, Silvana Babikian, Muhammad Yousaf.

Back row left to right: Svilen Stoyanov (co-chair), Darrick Heyd (co-chair), Malek El-Aooiti, Melanie Loiselle, Habiba Bougherara, Laurie Jacklin

Missing: Carey Barker, Ken Ozdemir

Last year, Ryerson’s JHSC onboarded new committee members to support active participation in committee meetings and discussions.

Completed certification training to meet regulatory requirements and to deepen knowledge and understanding of roles and responsibilities in preventing incidents and injuries at Ryerson.

Collaborated with EHS to develop a comprehensive workplace inspection strategy. The strategy will be implemented in 2019.

Last year, Ryerson received a Ministry of Labour order to submit a multisite JHSC application. This allows the ministry to evaluate if a central JHSC is appropriate for Ryerson. In preparation for this submission, the EHS team and the JHSC revised the committee’s Terms of Reference. The multi-site application was submitted to the ministry in December 2018 and we now await a decision.

Safety programs

EHS has developed multiple programs to enhance the safety of our faculty, staff, students and community. Developed in consultation with our community and in partnership with key contributors across the university, the programs are designed to meet the needs of our community.

EHS has developed multiple safety programs to meet the needs of our community.

Sharps Disposal Project

In response to concerns about an increase in the number of used needles found on campus, EHS implemented a successful sharps container installation pilot project in January 2018. Through collaboration with EHS, Maintenance and Operations and Facilities Services, 250 sharps containers were installed by the end of December 2018.

By July, 2019, all Ryerson washrooms will have a sharps container installed to provide a safe disposal method for sharps and needles.

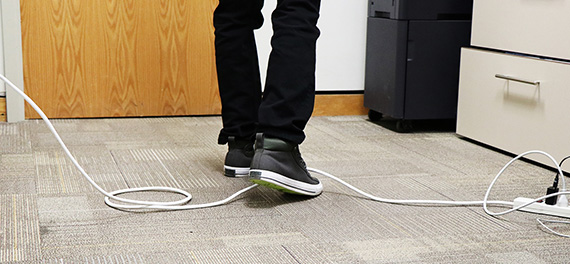

Near Miss, Incident and Injury Program

In 2018, EHS launched a (google form) new online form for Ryerson students, faculty and staff to report near misses, incidents, and injuries (external link) . Through the form, faculties and departments can submit a report in less than five minutes, and EHS can identify and trend key factors that may have led to an event or injury to prioritize response and prevention.

This form has led to rapid response for investigating critical injuries with EHS and the affected area.

In 2018, all eight critical injuries were reported to the Ministry of Labour within the allotted 24-hour time frame.

From 2017 to 2018, there was a 51% increase of events reported:

- In 2017, 59 events were reported.

- In 2018, 116 events were reported.

Occurrences are more actively shared within DSO and departmental meetings. Corrective actions are implemented more quickly.

Departmental Safety Officer (DSO) Program

The EHS team implemented a university-wide system of departmental safety officers (DSOs) and departmental safety committees (DSCs) to further embed safety into the culture and operation of every academic and non-academic unit on campus.

In 2018, 42 departmental safety committee meetings were held with a goal of addressing and resolving health and safety concerns, reviewing incident trends, providing consultative feedback on new safety programs and initiatives.

Departmental Safety Officers:

- Receive safety training.

- Guide their work units through safety inspections and incident investigations.

- Help to create customized safe operating procedures.

In 2018, Ryerson’s innovative Departmental Safety Officer (DSO) Program included over 110 DSOs appointed as the local health and safety resource for their relevant department.

In 2018, the Departmental Safety Officer (DSO) Program included over 110 DSOs appointed as the local health and safety resource for their department.

The EHS team implemented a university-wide system of departmental safety officers (DSOs) and departmental safety committees (DSCs) to further embed safety into the culture and operation of every academic and non-academic unit on campus.

Departmental safety committees are made up of:

- departmental safety officer

- program chair

- dedicated EHS manager

This collaborative approach allows for a strongly integrated safety management system and culture that is unique to each faculty and department.

In 2018, 42 departmental safety committee meetings were held to address and resolve health and safety concerns, review incident trends and provide consultative feedback on new safety programs and initiatives.

Laboratory Safety Program

In 2018, a comprehensive Laboratory Safety Program was developed to provide guidance for general laboratory procedures and processes including:

- the installation and maintenance of safety equipment (emergency eyewashes and safety showers and local exhaust systems),

- the use of and maintenance of personal protective equipment,

- information on the industry standards for laboratory design.

As part of the program, a comprehensive (PDF file) Personal Protective Equipment Manual is now available, as well as (google doc) Standardized Operating Procedures (SOPs) (external link) for common lab practices such as hazardous materials storage and handling, toxic waste management and disposal, and emergency procedures for accidents and spills.